Risks of implementing an ERP solution without a PLM solution

Several companies have been integrating ERP and PLM lately. The purpose of this article is to explore this topic and show us how useful this integration is.

Companies, in order to manage day-to-day business activities, such as accounting, warehousing, shipping etc. use Enterprise Resource Planning (ERP) software.

Indeed, ERP can be referred to as the “central nervous system of a firm” as it is essential for integrating and organizing data.

On the other hand, Product Lifecycle Management (PLM), helps managing the product life cycle due to the fact that it is a set of software solutions and business processes required to do it.

Not only PLM is significant for upgrading your company's management, but integrated with typical ERP data, together they become the perfect mix for efficient management for companies striving for product excellence.

We are Fourteen TEC, one of the most qualified SAP partners in Product Lifecycle Management.

We have implemented PLM processes for large multinational companies in all types of industries: from Discrete Manufacturing to Process Industry to Fashion Companies.

What is ERP

Customer needs, information and data keep increasing. This leads many companies today to be dissatisfied with data management and find themselves looking for ways to improve it.

But, a system called ERP has the purpose of increasing organizational efficiency by improving the way data is used.

With this system they are able to control accounting, issue invoices, manage inventory and have a total view of the data.

Does ERP work effectively alone?

Since ERP systems rely primarily on transactional data, most of these systems are:

Unable to organize specifications, documentation and product history, also known as Configuration Management

Unable to prepare accurate financial planning for new product development projects.

Unable to facilitate collaboration between departments around product changes.

Unable to highlight the changes taking place between Engineering and Manufacturing.

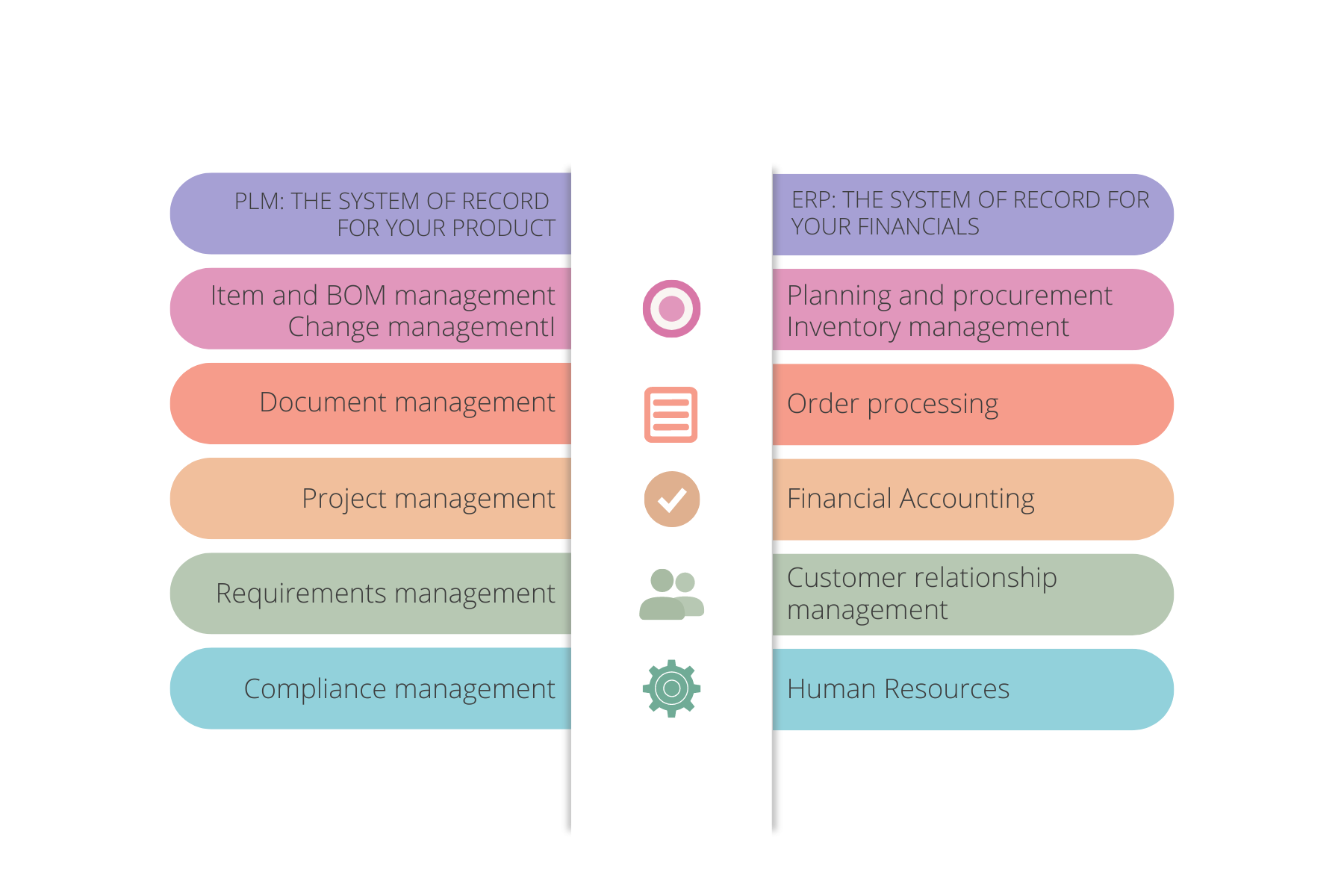

ERP vs PLM

Using ERP and PLM systems together, gives an organization complete control over its production processes, since they have distinct functionalities.

The managerial and operational core of the company is taken care of by the implementation of an ERP, since it controls it and organizes it.

PLM, on the other hand, gives total and integrated control over the setup of item information and processes at all stages of development, such as complex item information and related records such as issues and changes.

In this article we talked in detail about what PLM is.

These two solutions, however, are not interchangeable.

A PLM system provides a complete history of past, present and future changes to items, parts, assemblies (BOM) and more.

While an ERP system helps a company manage the transactional activities around the building of a product.

While ERP simplifies the management of accounting, invoicing, inventory management and helps to have a total view of income and expenditure, PLM helps to manage the entire product development phase and all its processes, from its creation.

4 benefits of implementing both ERP and PLM

The question is: are there any companies that have decided to implement both ERP and PLM?

Actually, there are many more than you imagine.

For several years now most multinational companies have already been enjoying the benefits of product lifecycle management (PLM) integrated with enterprise resource planning (ERP).

Increase efficiency and quality, reduce costs and errors that can occur during product development are allowed by implementing a PLM strategy.

The main advantages you will achieve by implementing both ERP and PLM are:

Increased Efficiency

Higher product quality with significant reduction in errors and rejects are going to be leading by the integration and synchronization of the management and operations area.

This improves product quality, automation, allows more flexibility, leading to improved production and market positioning.

Satisfied customers

Balance and efficiency within the company automatically leads to satisfied customers as you improve the quality of your products and reduce delays.

Costs reduction

Since by having more accurate data, the likelihood of error is minimized. Delays in deliveries will be avoided and you will always have an under control progress of product development.

You will also always have an overall, single, clear picture of business operations, making it easy to identify areas where costs can be reduced.

Better collaboration brings success

Clear and easy communication between different departments through integrated data management will lead to the disappearance of extra costs caused by communication errors.

SAP is the only enterprise platform that supports both ERP and PLM processes.

PLM and ERP have their own benefits, but their integration helps to take full advantage of each of the systems, gaining complete control over production and product data.

Organizational inefficiencies, transition costs, and time spent entering data and correcting errors will be greatly reduced, optimizing the entire organization.

If you want to be supported in the right implementation of PLM processes, Fourteen TEC is the market leader for the implementation of these on SAP.

Over the years we have developed application templates according to the industry and in a way that is tailored to the customer's needs.

You can contact us and schedule a meeting with one of our consultants.